In recent years, the advent of advanced technologies has transformed various industries, and the warehousing sector is no exception. One such groundbreaking innovation that has gained significant attention is the use of Autonomous Mobile Robots (AMRs) in warehouses. These intelligent robots are revolutionizing warehouse operations by streamlining processes and increasing efficiency.

The Rise of Warehouse AMR

warehouse amrs are autonomous robots designed to navigate through warehouse environments without human intervention. Equipped with sensors, cameras, and advanced algorithms, these robots can efficiently move around obstacles while carrying out tasks such as picking up items or transporting goods from one location to another.

By utilizing cutting-edge technology like simultaneous localization and mapping (SLAM), warehouse AMRs can create a map of their surroundings in real-time. This enables them to adapt to changes within the environment and optimize their routes for maximum efficiency.

The Advantages of Automated Picking

One key application of warehouse AMRs is automated picking. Traditionally, manual picking processes have been labor-intensive and time-consuming. However, with the introduction of automated picking using AMRs, this task becomes significantly more efficient.

Using computer vision systems combined with machine learning algorithms, warehouse AMRs can identify items on shelves accurately. They can then autonomously pick up these items based on predefined specifications or instructions received from a central control system.

This automation not only reduces errors but also increases productivity by minimizing human involvement in repetitive tasks. Additionally, it allows employees to focus on more complex responsibilities that require critical thinking skills.

Youibot: A Leader in Warehouse Robotics

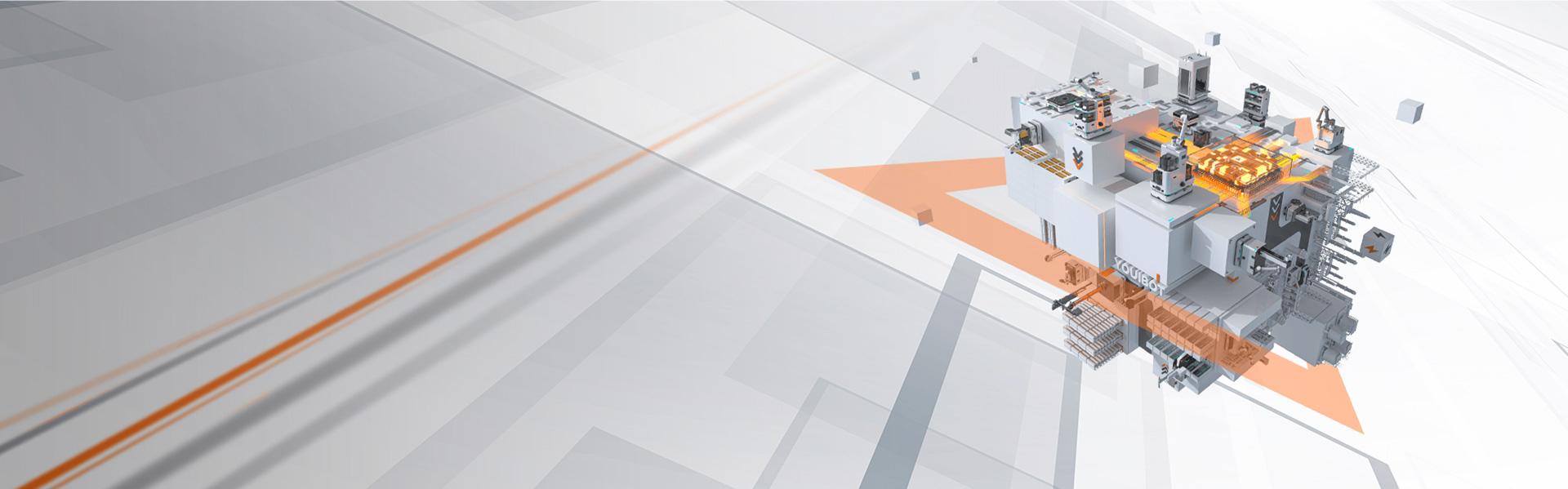

A prominent player in the field of warehouse robotics is Youibot – a company at the forefront of developing innovative solutions for logistics automation. Youibot offers a range of AMRs specifically designed for warehouse operations.

With their advanced navigation systems and robust hardware, Youibot’s AMRs can seamlessly integrate into existing warehouse infrastructures. These robots are capable of efficiently transporting goods, optimizing routes, and collaborating with human workers to enhance overall productivity.

Youibot’s commitment to continuous improvement and customer satisfaction has made them a trusted partner for businesses seeking to implement warehouse AMR solutions.

The Future of Warehouse AMR

As technology continues to advance, the potential applications for warehouse AMRs are expanding rapidly. From inventory management and order fulfillment to quality control and maintenance tasks, these intelligent robots have the capability to revolutionize various aspects of warehousing operations.

By leveraging the power of artificial intelligence, machine learning, and robotics, warehouse AMRs will continue to evolve in terms of capabilities and efficiency. The integration of these technologies holds immense promise for improving supply chain management while reducing costs associated with manual labor.

In conclusion, the introduction of warehouse AMRs has brought about significant advancements in the field of logistics automation. With their ability to navigate autonomously and perform tasks such as automated picking, these robots are transforming traditional warehousing practices. Companies like Youibot are leading this technological revolution by providing state-of-the-art solutions that optimize efficiency within warehouses. As we look towards the future, it is evident that warehouse AMRs will play an increasingly vital role in shaping the industry’s landscape.