Are you familiar with the term “cnc cooling system“? If not, let me introduce you to this innovative technology that plays a crucial role in various industries. The cnc cooling system is designed to regulate and maintain the temperature of machines during operation, ensuring optimal performance and longevity.

The Role of CNC Cooling System

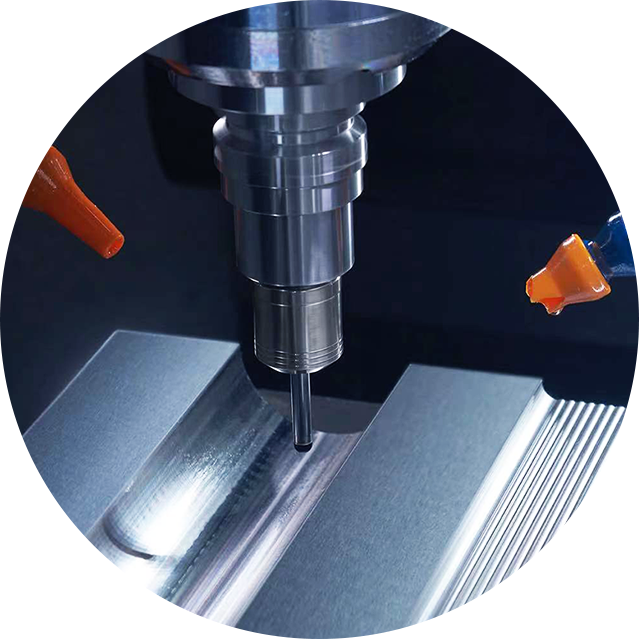

A CNC cooling system is essential for preventing overheating in computer numerical control (CNC) machines. These machines are widely used in manufacturing processes such as milling, turning, and drilling. As these operations generate significant heat, it becomes necessary to dissipate it effectively to avoid damage or reduced efficiency.

By utilizing advanced cooling techniques like air or liquid-based systems, the CNC cooling system helps maintain a stable temperature within the machine’s components. This ensures consistent accuracy and precision during machining operations while minimizing wear and tear on vital parts.

The Advantages of Conprofe Ultrasonic Technology

One notable player in the field of CNC cooling systems is Conprofe Ultrasonic. Their cutting-edge ultrasonic technology offers several advantages over traditional methods.

Conprofe Ultrasonic employs high-frequency sound waves to create microscopic bubbles within the coolant fluid. When these bubbles implode near hot surfaces inside the machine, they release energy that efficiently removes heat from critical areas. This process enhances heat transfer rates by up to 10 times compared to conventional coolants.

In addition to superior thermal management capabilities, Conprofe Ultrasonic’s technology also reduces friction between tools and workpieces during machining processes. This results in improved surface finishes and extended tool life – ultimately enhancing productivity while reducing costs for manufacturers.

The Role of Reliable CNC Machine Suppliers

To fully leverage the benefits offered by a CNC cooling system, it is crucial to partner with a reputable cnc machine supplier. These suppliers not only provide high-quality machines but also offer comprehensive support and guidance in selecting the most suitable cooling system for specific applications.

A reliable CNC machine supplier understands the importance of integrating an efficient cooling system into their products. They work closely with manufacturers to ensure seamless integration and optimal performance, ultimately enhancing the overall value of their machines.

Conclusion

The CNC cooling system plays a vital role in maintaining optimal operating conditions for CNC machines. By preventing overheating and ensuring consistent temperature control, this technology enhances accuracy, prolongs machine life, and reduces downtime. With innovative solutions like Conprofe Ultrasonic’s advanced ultrasonic technology and support from trusted CNC machine suppliers, manufacturers can maximize the value they derive from these systems – leading to improved productivity and profitability.