Understanding Prototype CNC Machining

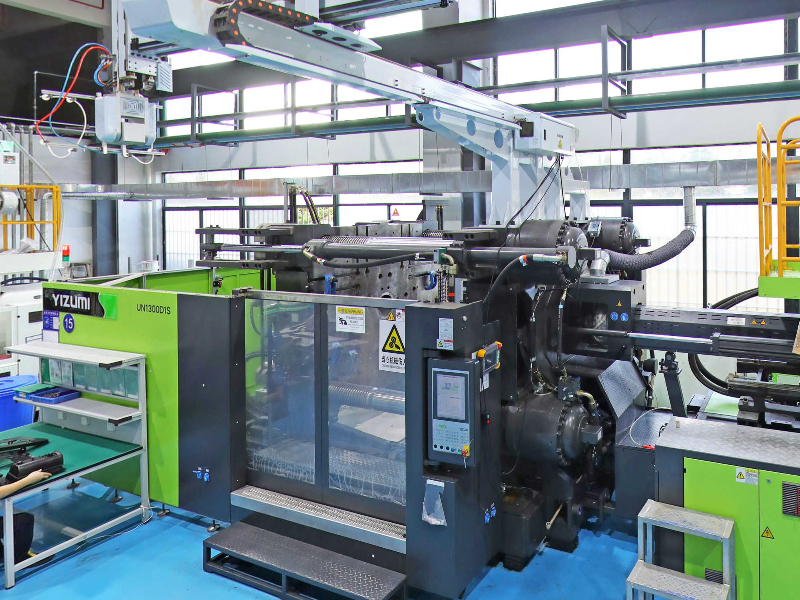

Prototype CNC machining has emerged as a fundamental aspect of modern manufacturing. This technology transforms raw materials into highly precise components, catering to industries ranging from aerospace to automotive. By leveraging advanced computer numeric controlled tools, manufacturers can create prototypes with exact specifications, ensuring that products meet rigorous standards before mass production. This process not only mitigates risks associated with design flaws but also shortens the time-to-market, enabling businesses to stay competitive. The utility of prototype cnc machining cannot be overstated, as it empowers engineers and designers to test concepts swiftly and cost-effectively while maintaining superior dimensional accuracy and repeatability.

Applications of Prototype CNC Machining

In practical terms, the applications of prototype CNC machining are vast. For instance, in the automotive sector, manufacturers can quickly produce parts for testing various vehicle designs, significantly reducing the lead time for new product development. Similarly, in the medical field, precise components for instruments or implants can be manufactured, enhancing patient outcomes and safety. The versatility of CNC machining allows for the prototyping of complex geometries, which are often difficult to achieve with traditional methods. By utilising prototype cnc machining, companies can innovate rapidly and respond to market demands with agility, ultimately leading to enhanced customer satisfaction and business success.

Custom CNC Services: Tailored Solutions for Diverse Needs

Custom CNC services offer a plethora of advantages for businesses seeking specific machining solutions. By collaborating with skilled technicians, organisations can obtain bespoke components that meet their unique design and functional requirements. This level of customisation ensures that the final product not only fits seamlessly but also performs optimally in its intended application. Furthermore, leveraging custom cnc services enhances flexibility in production, allowing companies to adapt to changing market demands without compromising on quality. This adaptability is crucial in today’s fast-paced environment, where the ability to pivot and innovate can make a significant difference in overall success.

Expanding on Custom CNC Services for Enhanced Productivity

When opting for custom CNC services, organisations can expect an extensive array of capabilities. These include the ability to work with various materials, such as metals, plastics, and composites, thus catering to multiple industry requirements. In practical scenarios, clients can commission prototypes that include complex assemblies or intricate designs, showcasing the versatility of CNC technology. By engaging in custom cnc services, businesses not only save time but also experience cost reductions associated with large-scale manufacturing, as potential issues can be identified and resolved during the prototyping phase. This preemptive approach to design validation is essential for maintaining high standards and operational efficiency.

Conclusion: Your Trusted Partner in Prototype CNC Machining

In summary, the significance of prototype CNC machining and custom CNC services cannot be understated in the realm of modern manufacturing. These technologies facilitate precision, flexibility, and innovation, critical elements in today’s industrious landscape. APT-Mold stands out as an exemplary manufacturer, ensuring supply advantages with their state-of-the-art capabilities and experienced team. By choosing to partner with APT-Mold, businesses gain access to not only high-quality machining services but also the support required to navigate complex design challenges. This strategic alignment fosters long-term relationships, built on trust and quality.